Piano di Manutenzione apparecchiature assiemate di protezione CEI IEC TR 63482:2024

| Appunti Impianti | ||

| Newsletter n. 99919 del 07 Luglio 2025 | ||

| Salve Visitatore | ||

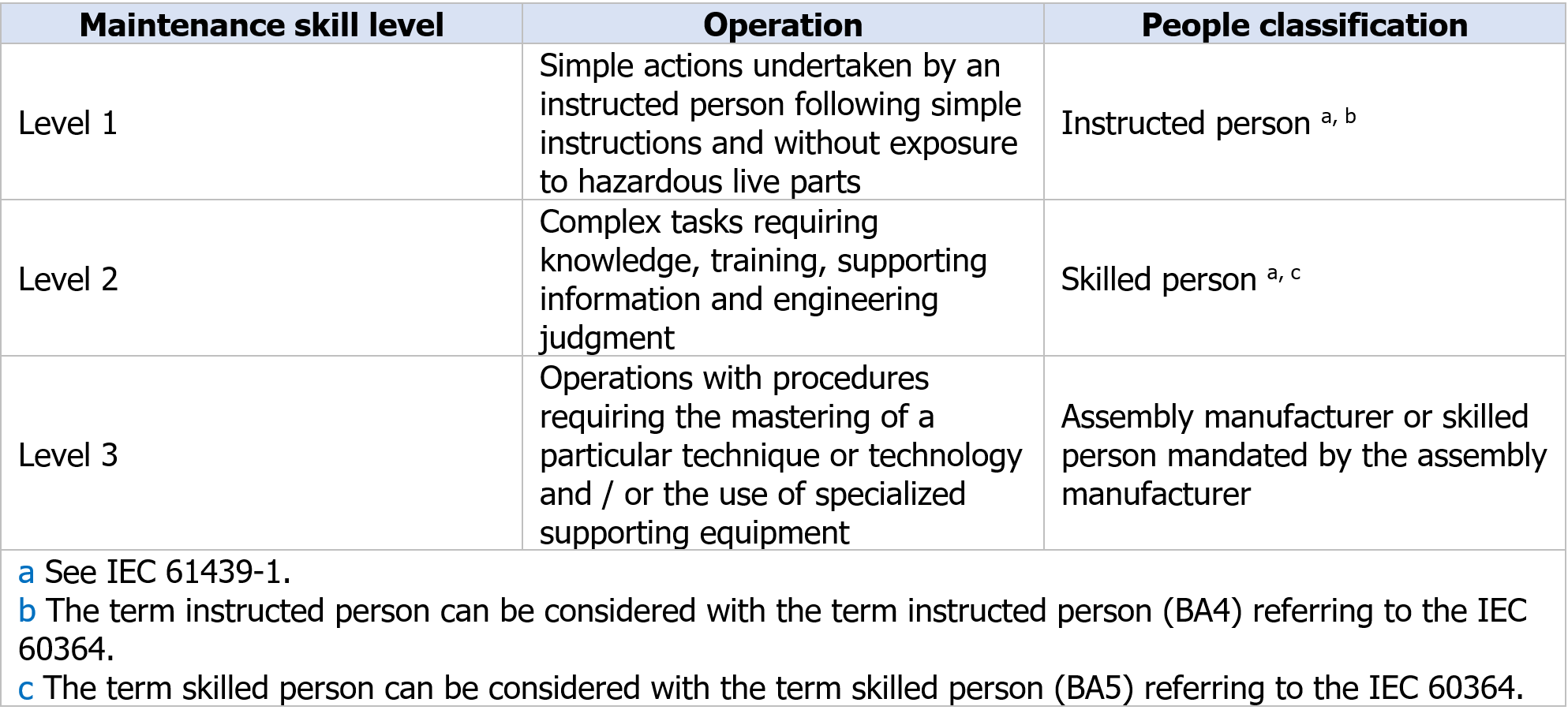

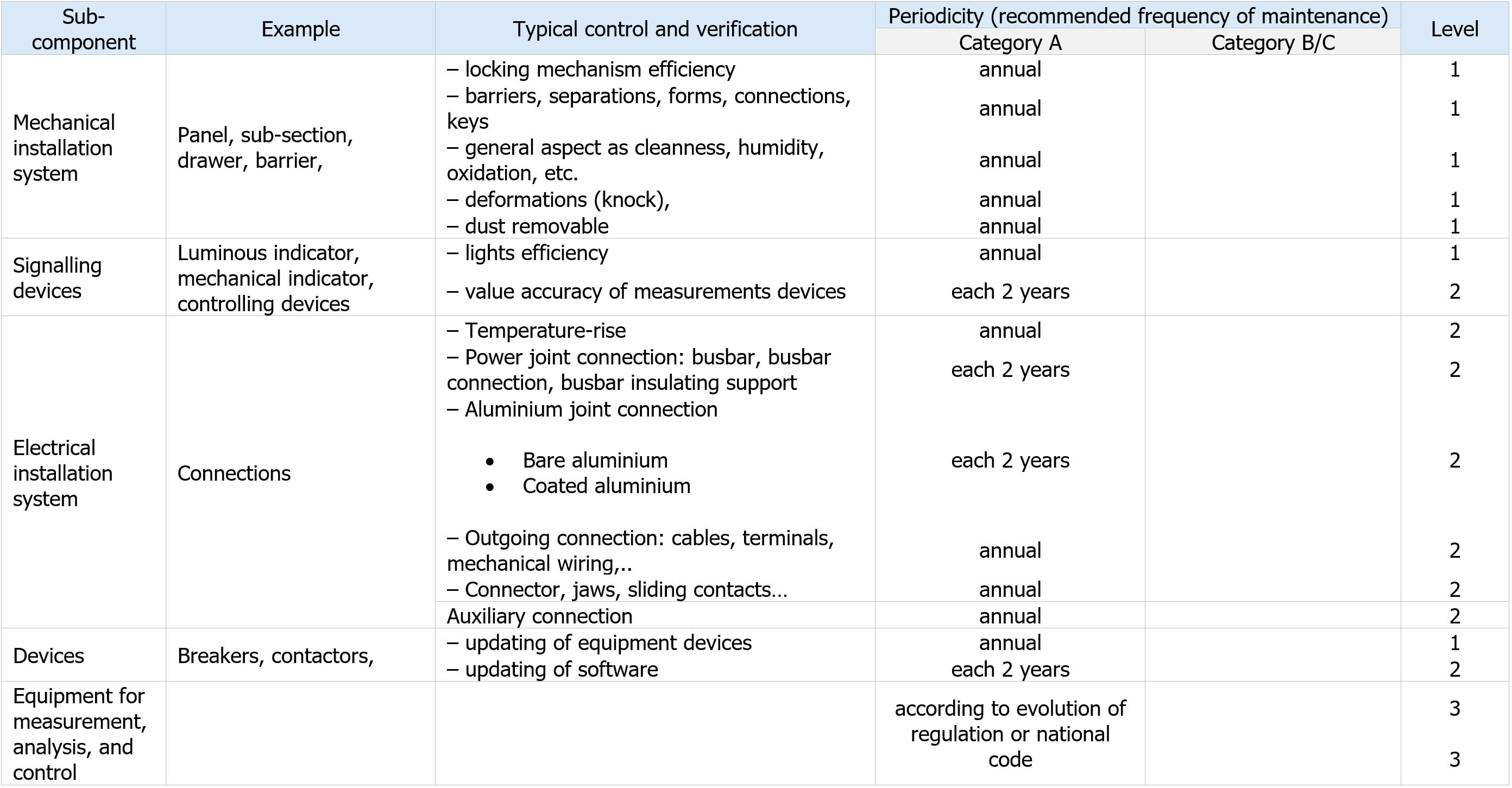

Piano di Manutenzione apparecchiature assiemate di protezione ID 23280 | 12.01.2025 / Documento completo allegato Il Rapporto Tecnico CEI IEC TR 63482:2024 si occupa della manutenzione di apparecchiature e di apparecchiature assiemate di protezione e di manovra aventi una tensione nominale fino a 1 000 V CA o 1 500 V CC inclusi e progettate per una frequenza nominale dell'alimentazione o delle alimentazioni in ingresso non superiore a 1 000 Hz. Il Rapporto Tecnico definisce delle linee guida per l’individuazione e la selezione del corretto approccio, per la pianificazione e l'esecuzione di attività di manutenzione. Nella Tabella A.1 dell’Allegato A vengono forniti esempi di operazioni di manutenzione in base alla tipologia di dispositivi e alla complessità delle operazioni di manutenzione (livello Skills da 1 a 3). [...] Extract Introduction In the low-voltage domain, the evolution of the IEC 61439 series of standards (low-voltage switchgear and controlgear assemblies) incorporating devices according to IEC 60947 series The IEC 61439 series is essentially dedicated to design and verification of assemblies up to the delivery to the customer. Most applications use assemblies to run 20 years or more. Over such long periods, without suitable maintenance, the performance of an assembly can To minimize the risk of malfunction due to ageing of the low-voltage assemblies some type of maintenance is implemented depending on local rules, customer maintenance policy or To avoid malfunctions, the schedules are usually conservative. As new technologies emerge, providing new functionalities and possibilities, for example measurement of equipment temperatures, loads including harmonic content, currents interrupted, climatic conditions, alternative and more effective maintenance approaches are possible. A preventive maintenance approach using such technologies can be more cost effective and This document shows that it is possible to provide one suitable maintenance approach NOTE 1 Scope This document provides guidance for the specification and selection of the appropriate This document provides guidance on the safety precautions for personnel designed to carry It recognises there are different approaches to maintenance, e.g. scheduled maintenance, condition-based maintenance and predictive maintenance. This document does not consider specifically corrective maintenance but many of the recommendations included would apply This document explains how the use of preventive maintenance improves the efficiency and lifetime of built-in components and consequently the assemblies themselves. All parties (specifiers, owners, designers, manufacturers, maintenance personnel) involved with It is also applicable to switchgear and controlgear assemblies intended for use under special service conditions, possibly with additional recommendations, for example in ships and rail vehicles. It also applies to low-voltage assembly upgrades which can have additional considerations to ensure modifications are fully verified to the appropriate assembly standard. This document does not apply to low-voltage switchgear and controlgear assemblies used in potentially explosive atmospheres. Finally, this document is not a substitute for national regulations regarding the safety of These are required to complement the overall principles defined in this document. […] 4.3 Good practice and procedures for establishing a safe working environment 4.3.1 Working procedures The risk assessment prior to commencing work is the recognized method of identifying safety risks. For maintenance activities on equipment, there is usually a written system of rules and procedures and all personnel involved with maintenance activities are aware of their existence. The level of detail and complexity of the rules and procedures is dependent on the organisation, personnel, working environment and equipment to be used. The risk assessment process is used to ensure that hazards specific to maintenance activities have been adequately addressed in the development of the associated rules and procedures. For example, different working practices and competencies are required for work on DCsystems than are required for AC systems. Safety rules set out the principles and practices expected clearly and in a format that can be understood by those expected to use them. The rules and procedures reflect the requirements of an overall electrical safety policy. In most circumstances a policy for workingon electrical equipment requires equipment to be deenergised and isolated prior to work commencing. Safety rules addressing specific issues such as circuits associated with: - interlocking and padlockingsupplies; All personnel are made aware to take notice of warning signs and follow instructions provided Product standards are recommended to include minimum requirements for the maintenance instructions to be provided by the manufacturer. […] 8 Implementation and management of maintenance 8.1 General Throughout its working life an assembly will u ndergo appropriate maintenance. Subject to the manufacturer’s documentation, maintenance of devices and assemblies is either scheduled, condition based, predictive or a combination of two or more the types of maintenance. For an example of a maintenance plan see Annex A. It is good practice to make sure software is available and can be modified as necessary, throughout the necessary anticipated lifetime of the assembly. Equally, necessary spares are available when required. Preventive maintenance is organized on the basis of inspections supplemented with operational checks followed by examination. The inspections and checks are of such a frequency to ensure that no undue damage or excessive wear is sustained in the course of operations since the last maintenance action. Examinations can be carried out to evaluate the possibly for reconditioning of the contact systems, lubrication and adjustment of mechanisms or deterioration of insulation. The appropriate intervals for examination are determined from the outcome of inspections or operational checks or are based on manufacturer’s documentation, taking into account operating duty, environmental conditions and the potential effects of failure. Inspection and testing of insulation are undertaken during examination. The different maintenance operations are based on different level of skills. [...] 8.2.2 Skill level 1 Tasks are simple actions undertaken by an instructed person following simple instructions and without exposure to hazardous live parts. Examples of the tasks as: - cleaning of the assembly; 8.2.3 Skill level 2 Tasks are complex, require knowledge, training, supporting information and engineering judgment. They are undertaken by a skilled person who understands the risks associated with partially energised equipment. Examples of the tasks as: - they are undertaken by a skilled person who understands the risks associated withenergised equipment; 8.2.4 Skill level 3 Operations with procedures require the mastering of a particular technique or technology and / or the use of specialized supporting equipment. These tasks are carried out by personnel with specialist skills, for example the assembly manufacturer or an organisation with the same expertise, and include: - Verification and update of software according to maintenance documentation; NOTE Table 1 classifies the maintenance operation in three levels in regard to their complexity and the necessary skills for each level. Table 1 - Maintenance operation level [...] Annex A (informative) Maintenance plan according to maintenance level The following Table A.1 give examples of maintenance operation related with the type of devices and the complexity of the operation of maintenance. Table A.1 - Maintenance plan [...] segue in allegato Certifico Srl - IT | Rev. 0.0 2025 Collegati |

||

|

||

|

è un sito di INVIO NEWSLETTTER Se vuoi cancellarti dall'invio della newsletter oppure effettua il login al sito ed entra nella Tua Area Riservata, in “Modifica dati” agisci con la spunta sul box di selezione “Newsletter”. L'elenco completo di tutte le ns newsletter è qui: Archivio newsletter certifico.com

Testata editoriale iscritta al n. 22/2024 registro periodici Tribunale di Perugia 19.11.2024 |

||

| Certifico Srl 2000-2025 | VAT IT02442650541 | ||