// Documenti disponibili n: 46.403

// Documenti scaricati n: 36.357.172

ID 23279 | 12.01.2025 / In allegato Preview

CEI IEC TR 63482:2024

Classificazione CEI: 121-30

Manutenzione delle apparecchiature e delle apparecchiature assiemate di protezione e di manovra per bassa tensione

Data Pubblicazione: 2024-12

Inizio validità: 2025-01

Questo Rapporto Tecnico si occupa della manutenzione di apparecchiature e di apparecchiature assiemate di protezione e di manovra aventi una tensione nominale fino a 1 000 V CA o 1 500 V CC inclusi e progettate per una frequenza nominale dell'alimentazione o delle alimentazioni in ingresso non superiore a 1 000 Hz.

Il Rapporto Tecnico definisce delle linee guida per l’individuazione e la selezione del corretto approccio, per la pianificazione e l'esecuzione di attività di manutenzione.

La presente Norma recepisce il testo originale inglese della Pubblicazione IEC.

________

Introduction

In the low-voltage domain, the evolution of the IEC 61439 series of standards (low-voltage switchgear and controlgear assemblies) incorporating devices according to IEC 60947 series (low-voltage switchgear and controlgear) have contributed significantly to improve safety, the performance and reliability of assemblies and power availability of low-voltage energy.

The IEC 61439 series is essentially dedicated to design and verification of assemblies up to the delivery to the customer. Most applications use assemblies to run 20 years or more. Over such long periods, without suitable maintenance, the performance of an assembly can be affected and unacceptably deteriorate with serious consequences for the safety of people and the application.

To minimize the risk of malfunction due to ageing of the low-voltage assemblies some type of maintenance is implemented depending on local rules, customer maintenance policy or assembly manufacturer instruction relating to the assembly or the built-in components within the assembly. Traditionally, maintenance is scheduled and has been predefined using a fixed schedule.

To avoid malfunctions, the schedules are usually conservative. As new technologies emerge, providing new functionalities and possibilities, for example measurement of equipment temperatures, loads including harmonic content, currents interrupted, climatic conditions, alternative and more effective maintenance approaches are possible.

A preventive maintenance approach using such technologies can be more cost effective and less disruptive than the traditional schedule-based maintenance arrangements.This document sets out the basic maintenance considerations for low-voltage switchgear, controlgear and their assemblies, which is supplemented by the assembly manufacturer’s instructions. It recognises that the traditional basic approach of maintenance can be improved and enhanced.

This document shows that it is possible to provide one suitable maintenance approach depending on the current customer’s application, but it is also possible to move to a more advanced maintenance approach, if an assembly is suitably upgraded.

NOTE

It is beneficial to refer to individual product standards and/or manufacturer instruction for further information on devices incorporated in an assembly.

1 Scope

This document provides guidance for the specification and selection of the appropriate approach and for the planning and the execution of the maintenance of low-voltage switchgear and controlgear and their assemblies having a rated voltage up to and including 1 000 V AC or 1 500 V DC, and designed for a nominal frequency of the incoming supply or supplies not exceeding 1 000 Hz.

This document provides guidance on the safety precautions for personnel designed to carry out maintenance services, with the aim to minimize the safety risks, optimize service continuity (power availability) and contribute to the environment of a low-voltage switchgear and controlgear assemblies.

It recognises there are different approaches to maintenance, e.g. scheduled maintenance, condition-based maintenance and predictive maintenance. This document does not consider specifically corrective maintenance but many of the recommendations included would apply when carrying out corrective maintenance. It provides additional recommendations to comply with validation requirements in IEC 60364-6.

This document explains how the use of preventive maintenance improves the efficiency and lifetime of built-in components and consequently the assemblies themselves. All parties (specifiers, owners, designers, manufacturers, maintenance personnel) involved with low-voltage switchgear and controlgear assemblies can benefit from this document. This document applies to both stationary and movable switchgear and controlgear assemblies with or without an enclosure.

It is also applicable to switchgear and controlgear assemblies intended for use under special service conditions, possibly with additional recommendations, for example in ships and rail vehicles. It also applies to low-voltage assembly upgrades which can have additional considerations to ensure modifications are fully verified to the appropriate assembly standard. This document does not apply to low-voltage switchgear and controlgear assemblies used in potentially explosive atmospheres.

Finally, this document is not a substitute for national regulations regarding the safety of electrical equipment and for the manufacturer’s maintenance instructions.

These are required to complement the overall principles defined in this document.

...

add Preview

Vedi Documento

Collegati

ID 1826 | 28.10.2025 / In allegato Modello Manuale completo

Modello di Manuale qualità in accordo con EN ISO 3834-2 per la sald...

UNI EN 474-11:2022 Macchine movimento terra - Sicurezza - Parte 11: Requisiti per compattatori per discarica

La norma, insieme alla UNI EN 474-1:2022, tr...

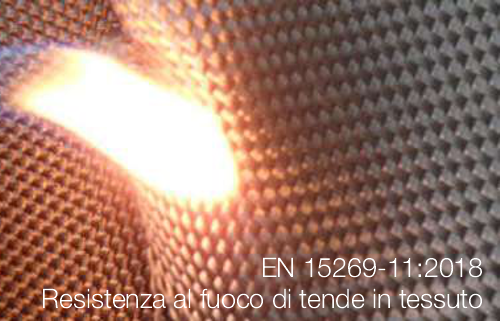

UNI EN 15269-11:2018 - Applicazione estesa dei risultati di prove di resistenza al fuoco e/o controllo della dispersione del fumo per porte,...

Testata editoriale iscritta al n. 22/2024 del registro periodici della cancelleria del Tribunale di Perugia in data 19.11.2024