Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO member bodies). The work of preparing International Standards is normally carried out through ISO technical committees. Each member body interested in a subject for which a technical committee has been established has the right to be represented on that committee. International organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards adopted by the technical committees are circulated to the member bodies for voting. Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 22000 was prepared by Technical Committee ISO/TC 34, Food products.

Introduction

Food safety is related to the presence of food-borne hazards in food at the point of consumption (intake by the consumer). As the introduction of food safety hazards can occur at any stage of the food chain, adequate control throughout the food chain is essential. Thus, food safety is ensured through the combined efforts of all the parties participating in the food chain.

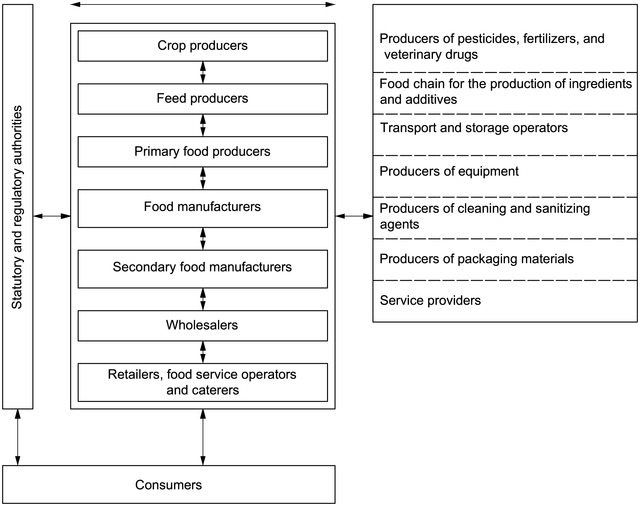

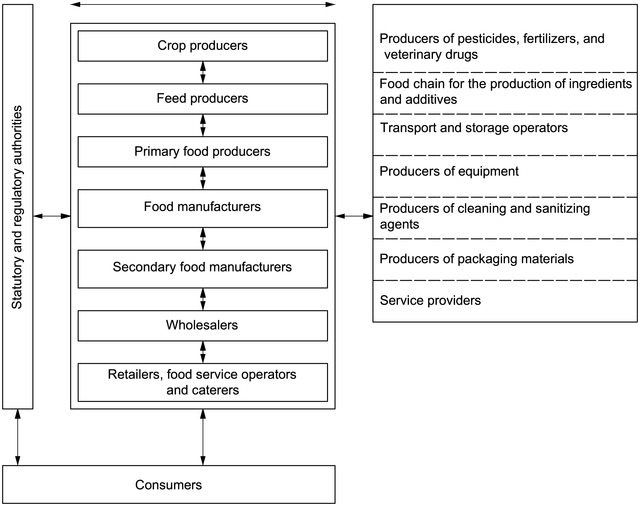

Organizations within the food chain range from feed producers and primary producers through food manufacturers, transport and storage operators and subcontractors to retail and food service outlets (together with inter-related organizations such as producers of equipment, packaging material, cleaning agents, additives and ingredients). Service providers are also included.

This International Standard specifies the requirements for a food safety management system that combines the following generally recognized key elements to ensure food safety along the food chain, up to the point of final consumption:

- interactive communication;

- system management;

- prerequisite programmes;

- HACCP principles.

Communication along the food chain is essential to ensure that all relevant food safety hazards are identified and adequately controlled at each step within the food chain. This implies communication between organizations both upstream and downstream in the food chain. Communication with customers and suppliers about identified hazards and control measures will assist in clarifying customer and supplier requirements (e.g. with regard to the feasibility and need for these requirements and their impact on the end product).

Recognition of the organization's role and position within the food chain is essential to ensure effective interactive communication throughout the chain in order to deliver safe food products to the final consumer. An example of the communication channels among interested parties of the food chain is shown in Figure 1.

The most effective food safety systems are established, operated and updated within the framework of a structured management system and incorporated into the overall management activities of the organization. This provides maximum benefit for the organization and interested parties. This International Standard has been aligned with ISO 9001 in order to enhance the compatibility of the two standards. Cross-references between this International Standard and ISO 9001 are provided in Annex A.

This International Standard can be applied independently of other management system standards. Its implementation can be aligned or integrated with existing related management system requirements, while organizations may utilize existing management system(s) to establish a food safety management system that complies with the requirements of this International Standard.

This International Standard integrates the principles of the Hazard Analysis and Critical Control Point (HACCP) system and application steps developed by the Codex Alimentarius Commission. By means of auditable requirements, it combines the HACCP plan with prerequisite programmes (PRPs). Hazard analysis is the key to an effective food safety management system, since conducting a hazard analysis assists in organizing the knowledge required to establish an effective combination of control measures.

This International Standard requires that all hazards that may be reasonably expected to occur in the food chain, including hazards that may be associated with the type of process and facilities used, are identified and assessed. Thus it provides the means to determine and document why certain identified hazards need to be controlled by a particular organization and why others need not.

During hazard analysis, the organization determines the strategy to be used to ensure hazard control by combining the PRP(s), operational PRP(s) and the HACCP plan.

Figure 1 - Example of communication within the food chain

NOTE The figure does not show the type of interactive communications along and across the food chain that by-pass immediate suppliers and customers.

Cross-references between the Codex Alimentarius Commission HACCP principles and application steps (see Reference [11]) and this International Standard are provided in Annex B.

To facilitate the application of this International Standard, it has been developed as an auditable standard. However, individual organizations are free to choose the necessary methods and approaches to fulfil the requirements of this International Standard. To assist individual organizations with the implementation of this International Standard, guidance on its use is provided in ISO/TS 22004.

This International Standard is intended to address aspects of food safety concerns only. The same approach as provided by this International Standard can be used to organize and respond to other food specific aspects (e.g. ethical issues and consumer awareness).

This International Standard allows an organization (such as a small and/or less developed organization) to implement an externally developed combination of control measures.

The aim of this International Standard is to harmonize on a global level the requirements for food safety management for businesses within the food chain. It is particularly intended for application by organizations that seek a more focused, coherent and integrated food safety management system than is normally required by law. It requires an organization to meet any applicable food safety related statutory and regulatory requirements through its food safety management system.

1 Scope

This International Standard specifies requirements for a food safety management system where an organization in the food chain needs to demonstrate its ability to control food safety hazards in order to ensure that food is safe at the time of human consumption.

It is applicable to all organizations, regardless of size, which are involved in any aspect of the food chain and want to implement systems that consistently provide safe products. The means of meeting any requirements of this International Standard can be accomplished through the use of internal and/or external resources.

This International Standard specifies requirements to enable an organization

-

a) to plan, implement, operate, maintain and update a food safety management system aimed at providing products that, according to their intended use, are safe for the consumer,

-

b) to demonstrate compliance with applicable statutory and regulatory food safety requirements,

-

c) to evaluate and assess customer requirements and demonstrate conformity with those mutually agreed customer requirements that relate to food safety, in order to enhance customer satisfaction,

-

d) to effectively communicate food safety issues to their suppliers, customers and relevant interested parties in the food chain,

-

e) to ensure that the organization conforms to its stated food safety policy,

-

f) to demonstrate such conformity to relevant interested parties, and

-

g) to seek certification or registration of its food safety management system by an external organization, or make a self-assessment or self-declaration of conformity to this International Standard.

All requirements of this International Standard are generic and are intended to be applicable to all organizations in the food chain regardless of size and complexity. This includes organizations directly or indirectly involved in one or more steps of the food chain. Organizations that are directly involved include, but are not limited to, feed producers, harvesters, farmers, producers of ingredients, food manufacturers, retailers, food services, catering services, organizations providing cleaning and sanitation services, transportation, storage and distribution services. Other organizations that are indirectly involved include, but are not limited to, suppliers of equipment, cleaning and sanitizing agents, packaging material, and other food contact materials.

This International Standard allows an organization, such as a small and/or less developed organization (e.g. a small farm, a small packer-distributor, a small retail or food service outlet), to implement an externally developed combination of control measures.

NOTE Guidance on the application of this International Standard is given in ISO/TS 22004.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 9000 and the following apply.

For the convenience of the users of this International Standard, some of the definitions in ISO 9000 are quoted with added notes that are applicable only to this special application.

NOTE Terms are not defined where they retain their normal dictionary definition. Where bold type is used in a definition, this indicates a cross-reference to another term defined in this clause, and the number reference for the term is given in parentheses.

3.1

food safety

concept that food will not cause harm to the consumer when it is prepared and/or eaten according to its intended use

Note 1 to entry: Adapted from Reference [11].

Note 2 to entry: Food safety is related to the occurrence of food safety hazards (3.3) and does not include other human health aspects related to, for example, malnutrition.

3.2

food chain

sequence of the stages and operations involved in the production, processing, distribution, storage and handling of a food and its ingredients, from primary production to consumption

Note 1 to entry: This includes the production of feed for food-producing animals and for animals intended for food production.

Note 2 to entry: The food chain also includes the production of materials intended to come into contact with food or raw materials.

3.3

food safety hazard

biological, chemical or physical agent in food, or condition of food, with the potential to cause an adverse health effect

Note 1 to entry: Adapted from Reference [11].

Note 2 to entry: The term “hazard” is not to be confused with the term “risk” which, in the context of food safety, means a function of the probability of an adverse health effect (e.g. becoming diseased) and the severity of that effect (death, hospitalization, absence from work, etc.) when exposed to a specified hazard. Risk is defined in ISO/IEC Guide 51 as the combination of the probability of occurrence of harm and the severity of that harm.

Note 3 to entry: Food safety hazards include allergens.

Note 4 to entry: In the context of feed and feed ingredients, relevant food safety hazards are those that may be present in and/or on feed and feed ingredients and that may subsequently be transferred to food through animal consumption of feed and may thus have the potential to cause an adverse human health effect. In the context of operations other than those directly handling feed and food (e.g. producers of packaging materials, cleaning agents, etc.), relevant food safety hazards are those hazards that can be directly or indirectly transferred to food because of the intended use of the provided products and/or services and thus can have the potential to cause an adverse human health effect.

3.4

food safety policy

overall intentions and direction of an organization related to food safety (3.1) as formally expressed by top management

3.5

end product

product that will undergo no further processing or transformation by the organization

Note 1 to entry: A product that undergoes further processing or transformation by another organization is an end product in the context of the first organization and a raw material or an ingredient in the context of the second organization.

3.6

flow diagram

schematic and systematic presentation of the sequence and interactions of steps

3.7

control measure

<food safety> action or activity that can be used to prevent or eliminate a food safety hazard (3.3) or reduce it to an acceptable level

Note 1 to entry: Adapted from Reference [11].

3.8

PRP

prerequisite programme

<food safety> basic conditions and activities that are necessary to maintain a hygienic environment throughout the food chain (3.2)suitable for the production, handling and provision of safe end products (3.5) and safe food for human consumption

Note 1 to entry: The PRPs needed depend on the segment of the food chain in which the organization operates and the type of organization (see Annex C). Examples of equivalent terms are: Good Agricultural Practice (GAP), Good Veterinarian Practice (GVP), Good Manufacturing Practice (GMP), Good Hygienic Practice (GHP), Good Production Practice (GPP), Good Distribution Practice (GDP) and Good Trading Practice (GTP).

3.9

operational PRP

operational prerequisite programme

PRP (3.8) identified by the hazard analysis as essential in order to control the likelihood of introducing food safety hazards (3.3) to and/or the contamination or proliferation of food safety hazards in the product(s) or in the processing environment

3.10

CCP

critical control point

<food safety> step at which control can be applied and is essential to prevent or eliminate a food safety hazard (3.3) or reduce it to an acceptable level

Note 1 to entry: Adapted from Reference [11].

3.11

critical limit

criterion which separates acceptability from unacceptability

Note 1 to entry: Adapted from Reference [11].

Note 2 to entry: Critical limits are established to determine whether a CCP (3.10) remains in control. If a critical limit is exceeded or violated, the products affected are deemed to be potentially unsafe.

3.12

monitoring

conducting a planned sequence of observations or measurements to assess whether control measures (3.7) are operating as intended

3.13

correction

action to eliminate a detected nonconformity

[SOURCE: ISO 9000:2000, definition 3.6.6]

Note 1 to entry: For the purposes of this International Standard, a correction relates to the handling of potentially unsafe products, and can therefore be made in conjunction with a corrective action (3.14).

Note 2 to entry: A correction may be, for example, reprocessing, further processing, and/or elimination of the adverse consequences of the nonconformity (such as disposal for other use or specific labelling).

3.14

corrective action

action to eliminate the cause of a detected nonconformity or other undesirable situation

Note 1 to entry: There can be more than one cause for a nonconformity.

[SOURCE: ISO 9000:2000, definition 3.6.5]

Note 2 to entry: Corrective action includes cause analysis and is taken to prevent recurrence.

3.15

validation

<food safety> obtaining evidence that the control measures (3.7) managed by the HACCP plan and by the operational PRPs (3.9)are capable of being effective

Note 1 to entry: This definition is based on Reference [11] and is more suitable for the field of food safety (3.1) than the definition given in ISO 9000.

3.16

verification

confirmation, through the provision of objective evidence, that specified requirements have been fulfilled

[SOURCE: ISO 9000:2000, definition 3.8.4]

3.17

updating

immediate and/or planned activity to ensure application of the most recent information