// Documenti disponibili n: 46.231

// Documenti scaricati n: 35.942.456

ID 23072 | 28.01.2025

Lo scopo del presente documento è quello di fornire una sintesi di linee guida di interesse per i siti di scarico di polimeri solidi trasportari alla rinfusa.

Allegati:

- BP Guidelines

- Check list scarico solidi alla rinfusa (polimeri) in cisterna ribaltabile (IT) doc/pdf

During the last years, the European Chemical Industry Council (CEFIC) and the European transport sector (ECTA) have developed guidelines for the safe logistics of chemicals.

Some of these guidelines are important for unloading sites of bulk solids in order to understand their responsibilities whilst trucks are delivering bulk solids and the risks from a safety, quality and legal perspective, which are associated with these operations.

The purpose of this document is to provide a summary of those aspects of these guidelines which may be of interest to polymers unloading sites. In addition it includes guidance on how the product quality can be preserved during the unloading operations by avoiding contamination or creation of streamers, angel hair, dust etc. This guideline should be used to raise awareness of all members of the supply chain including suppliers (commercial/sales), hauliers and customers (including intermediate storage).

FIg. 1 - Truck delivering bulk solids - Unloading of polymers in silo

The unloading site is responsible for:

- Providing a safe working environment for the unloading of materials.

- The safety of the driver, including providing site safety/unloading instructions.

- Providing suitable/well maintained infrastructure for the unloading.

- An unloading area equipped to prevent the loss of pellets to the environment and provision of basic cleaning tools.

- Informing the supplier of any unloading limitations/special requirements.

- Checking the validity of material arriving, documentation, seals and integrity.

- Checking and verifying the delivery paperwork to ensure the material is “as ordered”.

- Correct connection/fitting of product hoses to the storage silo and checking if the silo can accommodate the quantity to be transferred. Giving explicit approval to the driver to start the unloading.

- Ensuring that the infrastructure and unloading conditions are properly set, so that the transfer of product from trailer to silo does not lead to the formation of fines (streamers, angel hairs, dust) or other kind of impact or damage (see chapter 4).

. Supervising the unloading process (the checklist of annex B can be used as a guideline).

The driver and haulier is responsible for:

- Respecting all site safety rules.

- Respecting procedures to prevent pellet loss.

- Providing the delivery documentation.

- Supplying equipment that is fit for the operation, including seals and integrity.

- Correctly unloading the bulk truck and be fulltime present to observe the unloading process.

The supplier of the goods is responsible for:

- The quality of the materials supplied.

- Providing a safe working environment for the loading of materials.

- The safety of the driver at the loading site, including providing site safety/loading nstructions.

- A loading area equipped to prevent the loss of pellets to the environment and the provision of basic cleaning tools.

- Providing suitable/well maintained infrastructure for the loading of materials.

- Ensuring the haulier is aware of the tank cleaning requirements and checking compliance on arrival.

- Supplying documentation to identify the “quantity” and “quality” of materials.

The driver has the right to stop the unloading if at any point he feels it is not safe to continue (e.g. high winds, changes in unloading environment).

In case of accidental loss of pellets it is the responsibility of both customer and carrier to take appropriate measures to prevent further environmental impact (see chapter 5).

The requirements specified in the following chapters apply to both unloading and loading sites.

For more detailed information on responsibilities see Annex C of this document.

...

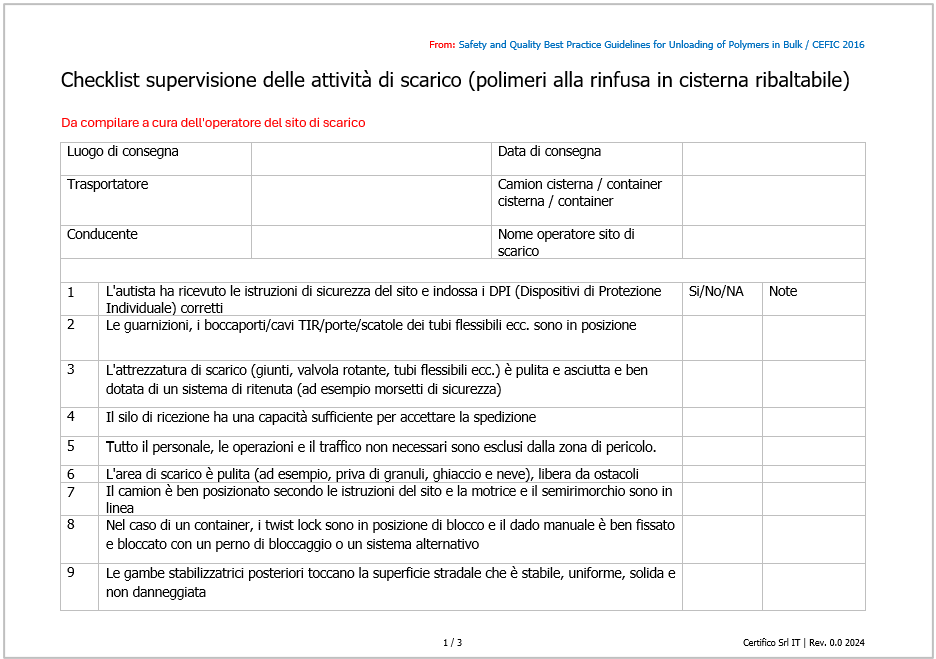

Checklist supervisione attività di scarico (polimeri alla rinfusa in cisterna ribaltabile)

Fig. 2 - Checklist supervisione attività di scarico (polimeri alla rinfusa in cisterna ribaltabile)

TABLE OF CONTENTS

1. Introduction

2. Roles and Responsibilities

3. Key requirements for safe unloading

4. Key requirements to maintain the product quality during unloading

5. Prevent Pellet Loss

Annex A - ECTA/CEFIC and PlasticsEurope reference documents

Annex B - Checklist for supervising the unloading activities

Annex C - Detailed roles and responsibilities

Contact list

CEFIC 2016

Collegati

European Agreement concerning the International Carriage of Dangerous Goods by Inland Waterways

Th...

ADR 2017: applicabile ai trasporti nazionali di merci pericolose

Recepimento della direttiva 2016/2309 della Commissione del 16 dicembre 2016 che adegua per la quarta volta al pr...

Multilateral Agreement M309 under section 1.5.1 ADR concerning cables in accordance with 9.2.2.2.1 ADR

(1) By derogation from the provisions of the second paragraph of 9.2.2.2.1 o...

Testata editoriale iscritta al n. 22/2024 del registro periodici della cancelleria del Tribunale di Perugia in data 19.11.2024