// Documenti disponibili n: 46.592

// Documenti scaricati n: 36.662.027

ID 6354 | 04.08.2023 Update CEFIC, July 2023

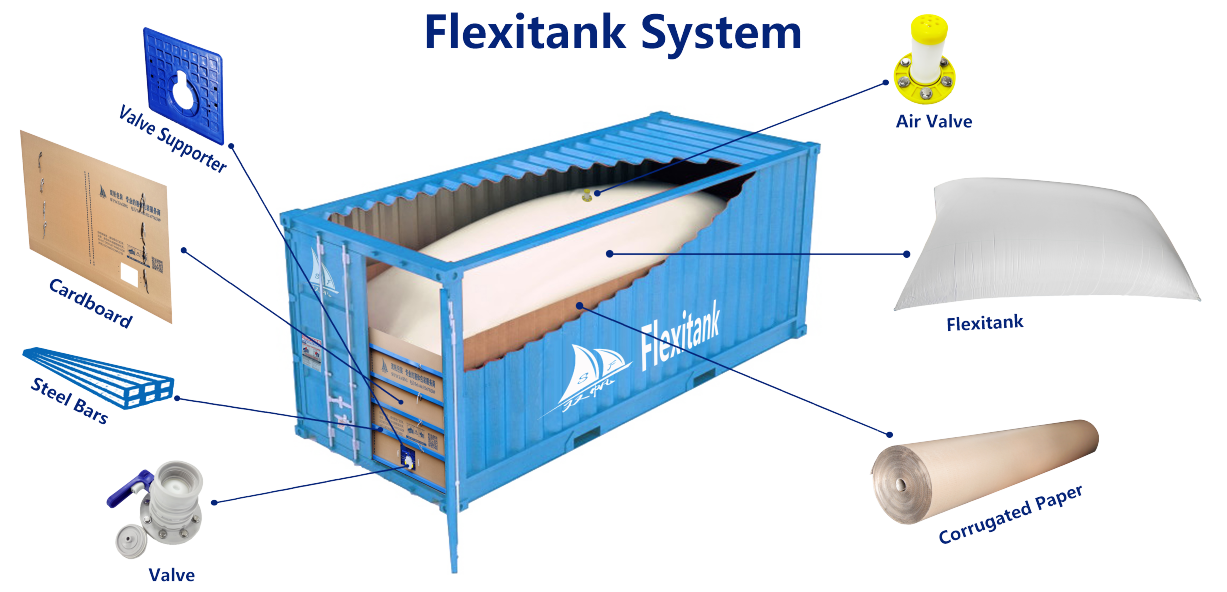

A Flexitank, also known as a Flexitank system, is a soft, light bladder, fitted within a standard 20-foot drybox container (see also chapter Definitions and Abbreviations for further details). The scope of these guidelines is restricted to the use of Flexitanks for the transport of bulk non-dangerous liquid cargoes within a general purpose (GP) 20-foot freight container. The bladder is generally intended for single use. Under the aspect of sustainability, it is important that the Flexibag system should be recyclable.

For the purpose of this guideline a Flexitank system as described in PAS 1008 will be referred to as a Flexitank. The bladder will be referred to as the Flexibag.

Transportation in Flexitanks of bulk chemical products not classified as dangerous goods is becoming an attractive alternative to transport in ISO tank containers. In the early days, a Flexitank damage resulted in leaks, loss of cargo and subsequent clean-up activities. The root cause was typically attributed to inappropriate handling and fitting and impact forces during transport of the Flexitank. In recent years, Flexitank producers and operators have achieved major improvements in bag manufacturing, container selection criteria, as well as safe loading and unloading practices. This has led to a reduction in the number of spills and leaks. These improvements, in combination with a continuous search by shippers for lower cost options for the transport of certain types of non-dangerous cargoes, has resulted in a significant increase of the number of Flexitank movements over the last decade.

Incidents involving Flexitanks pose a higher risk to result in a loss of containment compared to tank containers. The use of Flexitanks for the carriage of non-dangerous liquid chemicals should therefore only be carried out with the appropriate equipment and following the right operating procedures.

The continuous increase in use of Flexitanks and the importance of this intermodal transport unit make a review necessary. Certain areas of the 2018 Guideline have been updated, including: compatibility test criteria for a safe using of “Flexibag materials”, scope of responsibilities of each agent of the Flexitank Supply Chain, ISO 14001 or equivalent standard for Flexibag disposer and driver skills for road transport “leg”.

Fig. 1 - Example a Flexytank System

__________

1. Introduction

2. Objective and scope

3. Risk assessment

4. Equipment requirements

4.1 Container

4.2 Flexibag

4.2.1 Pressure relief and vent valves

4.3 Bulkheads

4.4 Loading equipment

4.5 Lining on walls of the freight container

5. Operating procedures

5.1. General

5.2. Loading/filling

5.2.1. Container preparation

5.2.1.1. Visual outside check of the container

5.2.1.2. Visual inside check of the container

5.2.1.3. Preparation and installation of the Flexibag

5.2.2. Filling/loading

5.2.3. Stop filling/loading

5.2.4. Labelling/marking

5.3. Temperature

5.4. Unloading

5.4.1. Heating of cargo prior to unloading

5.5. Flexibag disposal and assurance

5.6. Specific requirements for different modes of transport

5.7. Sampling

6. Flexitank manufacturer and operator qualifications

6.1. Flexitank manufacturer qualifications

6.2. Operator qualification and training

6.3 Drivers skills for the road transport “leg”

7. Incident Management

7.1. General

7.2. Accident Response

7.3. Incident Investigation

8. Checklists

8.1. Checklist for container selection

8.2. Checklist for Flexibag installation

8.3. Checklist before Flexibag filling

8.4. Checklist during Flexibag filling

8.5. Checklist after filling Flexibag

8.6. Checklist for unloading of the Flexitank

9. Agents involved in the Flexitank distribution chain

10. Definitions and Abbreviations

Fonte: CEFIC

ID 22179 | 04.07.2024 / ADR in Italiano GU

Pubblicazione della traduzione in lingua italiana del testo consolidato della vers...

Reference: C.N.744.2016.TREATIES-XI.B.14 del 10 Ottobre 2016

Entro il 1° ottobre 2016, nessuna delle parti contraenti del...

UN Recommendations on the Transport of Dangerous Goods Model Regulations 18a revised edition

Table of contents

Volume I (Recommendations, Parts 1 to 3, Dangero...

Testata editoriale iscritta al n. 22/2024 del registro periodici della cancelleria del Tribunale di Perugia in data 19.11.2024